DENSO Developed New Generation Battery-Monitoring Integrated Circuit for Lithium-ion Batteries, a Key component of Battery ECUs

- Written by ACN Newswire - Press Releases

|

|

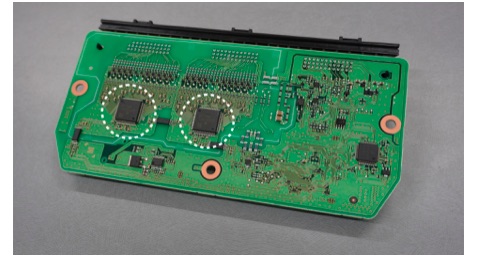

| Battery ECU / A battery ECU is designed to safely control the batteries in electric vehicles. Its key part is the battery monitoring IC for lithium-ion batteries, which monitors the voltage of lithium-ion batteries as power source of electric vehicles. |

|

|

| Battery monitoring IC for lithium-ion batteries |

This product is used in the Toyota Yaris, released in February 2020, and will be featured in future electric vehicles equipped with lithium-ion batteries.

To help address societal issues such as global warming, air pollution, and resource and energy shortages, it is crucial to accelerate the spread of electric vehicles, including hybrid vehicles and battery electric vehicles. With sustainability being one of the company's core tenets, DENSO has worked for decades to improve vehicle fuel efficiency, increase the performance of hybrid and electric vehicles, and develop technologies and products that help make vehicles less expensive, particularly those that are cleaner and greener.

The new IC can detect battery voltage three times more accurately (detection error: within 3 mV) and monitor 1.2 times more battery cells (25 ch/IC) than the conventional product DENSO developed in 2015.

DENSO's development of a high-accuracy reference voltage device, a key component in the battery-monitoring IC, has made it possible to use batteries more efficiently, thus improving the fuel efficiency and driving range of vehicles.

DENSO also has reduced the number of ICs and peripheral parts used for battery electronic-control units (ECUs). This, along with the company's development of deep sub-micron process technology and proprietary high breakdown voltage devices*, allowed DENSO to minimize the size and cost of battery ECUs.

DENSO is committed to contributing to the spread of electric vehicles to conserve the global environment and achieve clean mobility worldwide. To do this, the company continues to innovate cutting-edge technologies that make green transportation more efficient, more affordable, and more accessible to all.

*Joint development with TOYOTA CENTRAL R&D LABS.

For the full press release, visit https://bit.ly/312Tsad

About Denso

DENSO is a $48.3 billion global mobility supplier that develops advanced technology and components for nearly every vehicle make and model on the road today. With manufacturing at its core, DENSO invests in its 221 facilities in 35 countries to produce thermal, powertrain, mobility, electrification, & electronic systems, to create jobs that directly change how the world moves. The company's 170,000+ employees are paving the way to a mobility future that improves lives, eliminates traffic accidents, and preserves the environment. Globally headquartered in Kariya, Japan, DENSO spent 9.3% of its global consolidated sales on research and development in the fiscal year ending March 31, 2019. For more information about global DENSO, visit https://www.denso.com/global.

Copyright 2020 JCN Newswire. All rights reserved. www.jcnnewswire.com

Authors: ACN Newswire - Press Releases

Read more //?#